Description

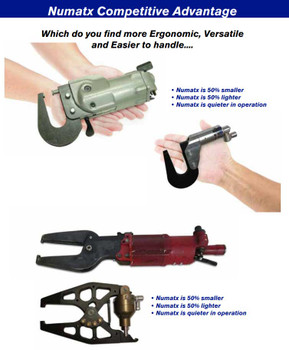

Numatx patented Hydropneumatic riveting system sets a new standard in aerospace and industrial compression riveting. Numatx rivet squeezers offer great ergonomic advantages in comparison to air only powered compression riveters. These C-yoke rivet squeezers are smaller, lighter, quieter, and more versatile for ease of operator use. Numatx distinct ergonomic advantages along with feathering control and constant force throughout the entire stroke, sets a new standard in rivet forming and operator productivity.

- Smaller unit fits in more spaces

- Much lighter than traditional compression rivet squeezers

- Much quieter operation

System Part Number: NXS-C6K4

Squeezer Head Included: NXC-6

Pressure Intensifier Unit Included: NXI-40

Squeeze Force: 6,445 lbs.

Yoke Reach: 4.0 inches

Yoke Gap: 1.5 inches

Hydraulic Pressure: 3,680

Numatx Hydropneumatic Rivet Squeezer Catalog PDF

Numatx Hydropneumatic Rivet Squeezer User Manual PDF

Numatx Rivet Squeezer DEMO VIDEO:

Current Commercial Users of Numatx Squeezers Include:

AIRBUS

ALCOA

BARNES AEROSPACE

BEECHCRAFT

BOEING AIRCRAFT

CANADA NATIONAL DEFENCE

DELTA AIRLINES

GE AIRCRAFT ENGINES

HONDA AIRCRAFT

KOREAN AEROSPACE

LODE KING INDUSTRIES

MUSCO SPORTS LIGHTING

NORTHROP GRUMMAN

ORENDA AEROSPACE

ROLLS ROYCE - UK

ROLLS ROYCE - US

SCHILLING ROBOTICS

SPIRIT AEROSYSTEMS

UTC AEROSPACE SYSTEMS

U.S. ARMY

U.S AIR FORCE

WHAT ARE NUMATX RIVETERS?

Numatx C-Squeezers and Alligator Squeezers are hydraulically operated hand held tools, designed to squeeze a variety of rivets during commercial riveting operations. These patented units are hydropneumatic actuated (also known as pneudraulic). Numatx intensifiers generate the necessary hydraulic pressure, and have been sized specifically to work with Numatx C-Squeezers and Alligator Squeezers. Since the hand-held portion of the riveters are fully hydraulic, Numatx units offer the advantages of decreased weight, reduced size, and constant force when compared to traditional pneumatic only squeezer. The reduction in weight and constant force decreases operator fatigue, and improves the quality of the riveting work. The units are built from high quality aircraft grade materials, with parts made on cnc machining centers and features held to close tolerances, for years of dependable operation.

The Numatx Hydropneumatic Riveter System (HPRS) is composed of a pressure intensifier and various hand held squeezers (forming heads). Different forming heads can be attached to a single intensifier, via hydraulic quick disconnects (QDs). The system uses compressed shop air at approximately 90 psig to generate hydraulic pressure at approximately 3,500 psig. For comparison this is roughy 100X the air pressure in a car's tire! This substantially higher hydraulic pressure is then used by the forming heads to form rivets or perform other related tasks such as crimping and staking. The high pressure hydraulic fluid allows for smaller and lighter rivet squeezers.

Hy`dro`pneu`mat´ic

a. Pertaining to, or depending upon, both liquid and gaseous substances; as, hydropneumatic apparatus for collecting gases over water or other liquids.

All other squeezer units that produce peak force, produce their maximum force at approximately the final 1/8" (3mm) of tip travel. This means that you WILL need to adjust the length of the rivet set, or alligator tip length frequently when squeezing varying rivet lengths. This is accomplished with different length rivet dies, shims and so forth. AND you may need to squeeze a rivet twice, to fully form the rivet. Try squeezing different length rivets with a traditional squeezer, and you will find this to be true. If you have a pattern of say 50 rivets to squeeze, you may need to squeeze each rivet twice, resulting in wasted time and increased fatigue.

Numatx measured the force of a traditional 3K (3,000 Lbf) C-Squeezer, using a load cell (see below). The maximum force was first found by adjustment of the rivet set length, then the rivet set length was adjusted while additional measurements of force where taken. The results are presented below.

KEY POINT: The force of a traditional pneumatic only squeezer may drop by more than 60% in only .060" (1.5mm) of rivet set variation.

No. ALL other squeezers available today, whose design really has not changed much for over 40 years, produce "peak" or varying force.

In operation, the traditional squeezer has an air piston (56) which forces a the tip of a wedge (60) against a roller (42) which act as a lever on the alligator jaw or C-Squeezer rivet set. The roller is forced up the curved incline of the wedge. Since the wedge tip is curved, the roller rises most rapidly at the beginning of the piston travel, and then more slowly as the wedge angle shallows. When the roller is travelling along the shallow portion of the wedge (near the #58), the riveter is producing the maximum force. This is the point at which the rivet is being squeezed.

The rapid movement of the tip creates a "Bear-trap" like action, which many experienced users do not like, as it increases the possibility of mis-squeezing a rivet. The hydraulic action of the Numatx units produce a smooth linear rate movement, which users find very controllable.

How are the units charged with hydraulic fluid and bled of air if necessary"

A simple 30 or 60cc syringe and 1/4" OD tubing supplied with the Intensifier unit is all that is needed to charge and bleed the unit of any trapped air in the system. As it is with an auto's brakes, it is important to remove any air bubbles from the system, which would otherwise compress and rob the squeezer head of stroke. The system is oriented with the forming head (squeezer) at the highest position, and with no sags in the hydraulic line. The hydraulic fluid (Dexron III ATF) is injected into the bleed fitting on the intensifier, which has been loosened slightly to unseat the fitting from the Intensifier high pressure cylinder. Once it is observed that no more bubble are leaving the drain tube, the bleed fitting of the intensifier is tightened, the syringe and tubing removed, and the bleed plug reinstalled into the squeezer. The fluid should come to the top of the squeezer bleed plug port, and a small amount of fluid can be added to "top off" the unit. The system is then ready for use.

What kind of warranty is available? Will this product last a "lifetime" with proper care and use?

The warranty is 6 months for parts/labor on any defect. With normal use and care, the units will last a lifetime. The units are constructed from hight quality materials and coatings. Parts are precision machined from aircraft grade bar-stock and plate materials, such as 7075 and 6061 aluminum or 4140 PHT steel. Anodize, black oxide, and other coatings are used for corrosion and wear resistance. Bottom line: The units are made to endure demanding production environments.