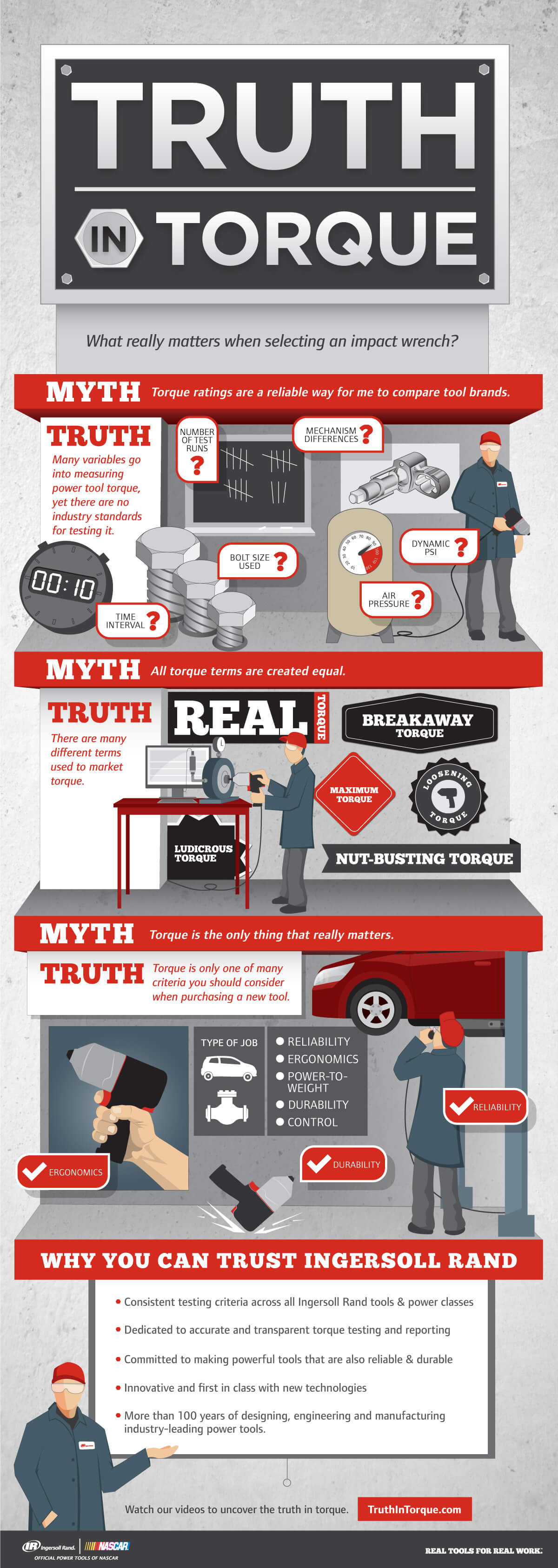

All Torque Is Not Created Equal- The Truth In Torque by Ingersoll Rand

Torque plays a crucial role in industrial applications, defined as the product of the lever arm length and applied force. For example, if a two-foot long bar holds a 10-pound weight, it generates 20 foot-pounds of torque. Determining the appropriate torque for a specific job involves considering the size of the bolt. Bolt requirements dictate torque specifications, focusing on the bolt itself rather than the torque equation mentioned earlier. Larger bolts can handle higher torque without stripping. Insufficient torque increases the risk of bolts loosening and falling out, while excessive torque can cause stretching, stripping, or even breakage.

Warren Seith, Ingersoll Rand Innovation Development Manager, emphasizes that many mechanics tend to apply excessive torque in their work. While an application may require only 80 foot-pounds, some mechanics use 300-400 foot-pounds, posing a danger of bolt breakage. Ingersoll Rand impact tools serve specific purposes. It's important to note that impact tools are reactionless, which means the operator cannot feel the amount of torque applied or gauge the tightness of the bolt.

While impact tools have their significance in the shop, there are better methods for properly tightening bolts. They prove particularly useful when removing tight, rusted, or frozen bolts, as they facilitate quick removal. Seith suggests a two-step approach when tightening bolts: first, snug the bolt slightly with an impact tool and then finish the tightening process with a hand torque wrench or click wrench. This method allows measurement and ensures that the bolt is not over-tightened. Increasingly, tire shops are recognizing the importance of this approach, driven by the need for customer safety. Over-tightened lug nuts can cause tires to fall off or result in lug nut breakage.

To avoid over-tightening lug nuts or other safety-critical fasteners, torque sticks can be used to ensure proper tightening within the recommended torque values provided by car manufacturers. The torque specifications for lug nuts can typically be found in the vehicle's manual. The breaking point of a bolt varies based on the specific application and bolt size.

For removing lug nuts, the Ingersoll Rand 2235TiMAX, a half-inch impact tool, is an excellent choice, especially when dealing with rusted, frozen, or over-tightened lug nuts. However, it is too powerful for reinstalling them. Paying careful attention to the amount of torque applied to lug nuts or bolts is essential to ensure a safe and successful outcome.

Recent Posts

-

Prolonging the Lifespan of Air Motors: Essential Maintenance Tips

Air motors are vital components in various industries, powering a wide range of applications. To max …Jun 3rd 2023 -

Powering Efficiency: Five Applications Benefiting from Air Motors

Air motors are versatile and reliable devices that find extensive use across various industries. The …Jun 3rd 2023 -

The Top 5 Reasons Industrial Customers Choose Ingersoll Rand Screwdrivers

When it comes to industrial applications, having reliable and efficient tools is crucial for prod …Jun 3rd 2023