Description

8670-28-3 Specifications

| Model | 8670-28-3 |

| Sound Level dB(A) | 80 |

| Air Consp. @ Working Speed ft^3/cycle (L/cycle) | 5.0 ( 142 ) |

| Nominal Drilling Capacities Wood, Med. or FRP | 5/8 (15.9) |

| Thrust @ 90 PSI lb. (N) | 500 lbs. |

| Free Speed rpm | 2,800 |

| Nominal Drilling Capacities Stnls. Steel Type 304 | 3/16 (4.8) |

| Std. Chuck Capacity in. (mm) | 3/4" ( 19mm ) |

| Stroke Length in. (mm) | 3.0 ( 76 ) |

| Nominal Drilling Capacities Steel SAE 1213 | 1/4 (6.35) |

| Nominal Drilling Capacities Aluminum 2024-T4 | 9/16 (14.3) |

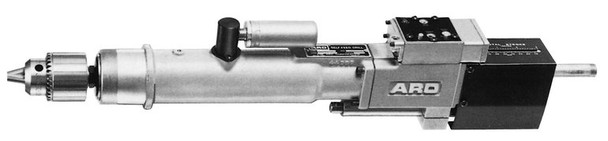

5/8" (15.9 mm) Capacity, Steel 1.25 HP (.93 kW) ARO Hi-Thrust Automatic Feed Drills are designed for increased material removal rates of standard alloys and non-ferrous materials. Their high power and thrust also enable the machining of even the most demanding materials, including titanium and high-nickel alloys. ARO Hi-Thrust Drills feature a dual piston which develops the increased thrust for fast penetration and reduced cycle times. The tools are fully automatic, with all cycle and motor functions regulated by a single control module. They are easily installed, requiring only simple pneumatic circuity. Hi-Thrust Drills can also be used in conjunction with other pneumatic and electric ARO Automatic Production tools.

- Adjustable hydraulic check provides positive feed rate control for fine adjustment of chip size or breakthrough control.

- "Dead stop" and "dwell" control offer repeatable depth accuracy within .001"

- Heavy-duty cast iron housing for rigid mounting.

- Constant tool length, regardless of spindle speed, allows speed change without repositioning the tool.

- Both coarse and fine stroke length adjustments enables quick, accurate setups.

- Control module ia s complete, replaceable unit and can be easily removed without tool disassembly.

- Modular motor and gearing units enable fast, easy speed changes and servicing.

- Single exterior lubrication point for entire gear train simplifies preventative maintenance.

- Muffled exhaust for a more comfortable work environment.

- Exhaust may be piped away.

To view our complete selection of air and electric drills, click here to return to Drills and Tappers - Home.